Reticular vitreous carbon is a three-dimensional, microporous material made from glassy foam, featuring a high void ratio of 90%-97%, low density (0.03g/cm³), excellent chemical stability, and impressive specific surface area and conductivity. It also boasts low thermal conductivity and expansion, high structural strength, and minimal fluid resistance. This type of electrode shows great potential in applications such as organic electrochemical synthesis, electrocatalytic reactions, and electrochemical research.

<span style="font-weight: 400;">High-quality FTO glass slides coated on a soda lime float glass. </span>

<span style="font-weight: 400;">Available sizes 10 x 20 mm, and 100 x 100 mm with a plate thickness of 1.1 mm (Pack of 50).</span>

<span style="font-weight: 400;"> Customization is also available.</span>

High-quality ITO glass slides coated on a soda lime float glass.

Available sizes are 10 x 20 mm, and 100 x 100 mm with a plate thickness of 1.1 mm (Pack of 50).

Customization is also available.

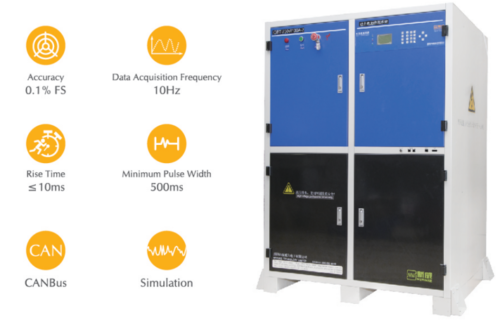

The super capacitor testing system is an analysis and diagnosis system. It test the performance of various super capacitors under different testing conditions

This series is especially designed for huge battery packs: EV battery packs, stationary storage battery packs, etc. could be customized both in voltage and current output ranges.

These are the real flagship models among all the Battery testers. They have ruled the cylindrical and small pouch cells test market for a long time.

These are the real flagship models among all the Battery testers. They have ruled the cylindrical and small pouch cells test market for a long time.

These are the real flagship models among all the Battery testers. They have ruled the cylindrical and small pouch cells test market for a long time. As time goes by, battery and battery testers are both changing, higher density and quick charge / discharge requirements make these the new star.

Download Now

It is an excellent tool to make quality film for material research in laboratory to make ceramic tape casting, battery electrodes, and various coating at lower cost. Stainless steel knife blade with precision ground edge.

Multi-groove coating device is designed for use on a flat substrate coating uniformly paint, adhesives and similar products.

The split test cell is used for rechargeable battery and battery electrode materials research

Coin cell crimper is a newly designed coin cell sealing machine with lighter weight. It can also be used for disassemble purpose with disassemble die.

The coin cell disc cutter is used for coin cell electrode punching with customized cutting die. The resulting discs can be used as electrode/separator discs of split test cell and coin cell for battery researchers.

It is a desktop manual pressing machine for materials / chemistry research laboratories to prepare compound ceramic sample.

This is a compact hot rolling press machine mainly serves for pressing samples in the lab or other

applications in the material research especially for increasing active material density of the electrode in Li-ion batteries research after coating.

This is a compact precision electric rolling press machine. It has dual rollers and dual grade micrometer. It is an ideal rolling press for adjusting thickness and increasing active material density of the electrode in Li-ion batteries research after coating and drying.

This is a manual rolling press machine. It has dual rollers and dual grade micrometer. It is an ideal rolling press for adjusting thickness and increasing active material density of the electrode in Li-ion batteries research after coating and drying.

The film coating machine with dryer is used for varies kinds of materials coating. It is supplied with Internal vacuum pump and heating system, with a precision heating temperature upto 200℃.

It is one high efficiency equipment with vacuum molding and dispersion function, suitable for the battery lab research of anode and cathode electrode slurry mixing process, as well as for the powdered and ceramic materials mixing.

PRODUCT DESCRIPTION

The vacuum oven is used for lithium battery materials, electrodeand battery core vacuum dying.

This vacuum mixer is vacuum mixing, dispersion efficient equipment, it is suitable for battery electrode paste and various ceramic materials mixing, due to complete the process in vacuum station, fully implemented without air bubbles, improve the filling material and density.